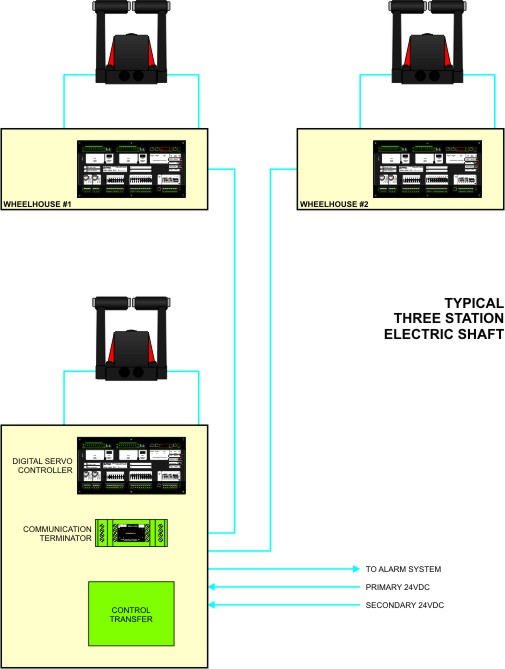

| Electric Shaft System

Series 8503-2000 Digital Servo Controller are used in conjunction with Type

5040-1100 control heads to form an electric shaft system.

The electric shaft control system is an electrical alternative to mechanical shafting for interconnecting control levers on a ship.

Moving the control lever at one station causes all other levers in the system to follow. This provides continuous display of the commanding lever position at all stations. Because all control levers are continually aligned, control transfer between stations is smooth and

“bumpless”.

The system uses dual 24 VDC inputs from ship’s power supplies and serial communication with error detection to ensure trouble free operation.

Command Orders

To place a new command: Ensure that the station you are operating is in command. Move the Command Lever to the desired command position. This will transmit the new command position to all the stations. All other stations (unless disabled) will align their Command Levers to the new command position.

Command Jog

Jog buttons can be added, allowing the operator to make fine adjustments to the Command Lever position.

|

Control Transfer

Generally, command is transferred by pressing a Control Transfer button. Optional auto transfer is available, where moving the Command Lever at the desired control station will also transfer command.

The control transfer logic can be performed by the Digital Servo Controller or via external logic (PLC, relays, control transfer boards).

Command Position

Optional command signal transmitters can be installed at the factory. These transmitters work independently of the electric shaft circuitry in the Digital Servo Controller. Each transmitter has it's own power supply with a self resetting internal fuse. Even with a complete failure of other circuitry on the Digital Servo Controller the transmitter will continue to function

properly.

Diagnostics

Troubleshooting guidance is provided by a Watchdog LED and a Fault Code LED. Under normal operating conditions the Watchdog LED will flash.

The Fault Code LED flashes two digit codes which correspond to particular fault conditions.

A fault relay opens on a general system fault. A critical fault relay opens when a fault is detected in the system that would cause an electric shaft lever to

stop operating correctly.

|