| Propulsion Order

Telegraph System Series 8503-2000 Digital Servo

Controllers are used in conjunction with Type 5401-1100 telegraph heads to

form a traditional lever style telegraph system.

The propulsion telegraph system provides a means of

bi-directional communication between the bridge and the engine room. This

communication is in the form of orders placed and acknowledged by moving the

command levers.

The system uses dual 24 VDC

inputs from ship’s power supplies and serial communication with error

detection to ensure trouble free operation.

Relay outputs are provided for an order bell and a wrong

direction alarm.

Telegraph Orders

An order is placed by moving the lever at the bridge

station in command to the desired order. This causes the reply pointers at

all engine room stations to move to the same position as the command lever

on the bridge.

Whenever the reply pointer and the lever at an in command

telegraph are not aligned, the external bells sound, at both in command

locations, to indicate a new order.

Once the in command engine room lever is moved to align

with it’s own reply pointer, all bridge reply pointers will follow up and

align with the engine room lever. All audible devices will silence. The

engine room can transmit orders to the bridge in the same manner.

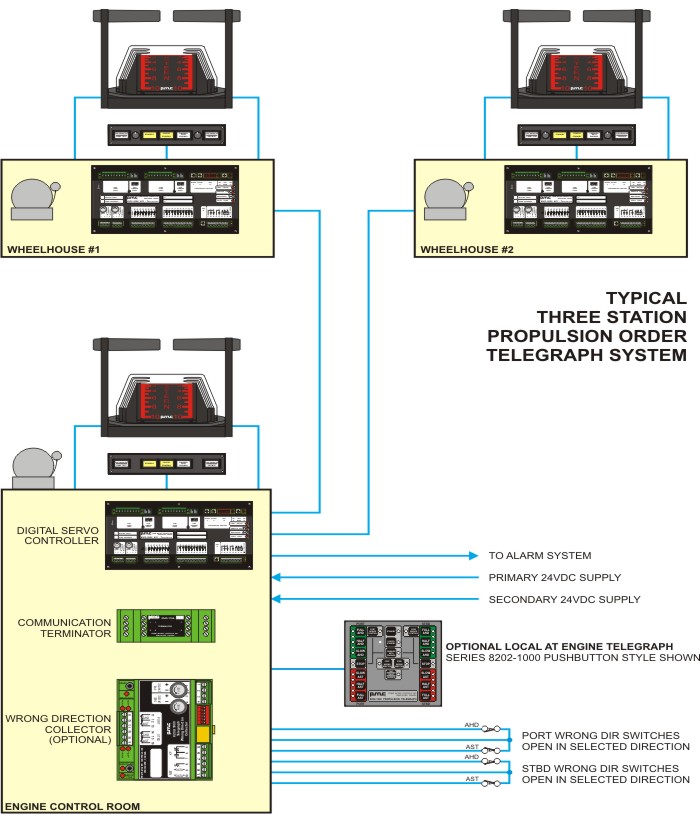

Multiple Station System

The propulsion telegraph system can operate from multiple

bridge and engine room stations.

When a ship has one bridge station and one engine room

station, both the bridge and engine room station are always in command.

When a ship has more than one station in the bridge and/or

more than one station in the engine room command transfer is required.

Generally a telegraph command transfer button is used to transfer command.

The control transfer logic can be performed by the Digital

Servo Controller or via external logic (PLC, relays, or control transfer

boards). |

Auxiliary Orders

Auxiliary telegraph orders such as Standby, Cancel Standby

and Finished With Engines can be integrated into the lever telegraph.

Auxiliary telegraph orders can also be external pushbuttons.

Wrong Direction

An optional wrong direction alarm, with adjustable time

delay, is activated when the direction of propulsion is not the same as the

acknowledged telegraph order. This feature advises the engineer and captain

when the machinery direction does not match the acknowledged order or if the

machinery drifts to a direction other than the established setting. Ahead,

Stop and Astern are considered distinct directions and are monitored by the

wrong direction circuitry.

When auxiliary telegraph orders are present on the lever

telegraph scale, wrong direction alarms are disabled for any acknowledged

auxiliary order. When external push buttons are used for the auxiliary

telegraph orders, wrong direction alarms are disabled for acknowledged

Finished With Engines and Bridge Control orders, but enabled for Standby and

Cancel Standby orders.

Pushbutton Telegraph Stations

Series 8202-1000 Push Button Telegraphs can be connected

to a Series 8503-2000 Digital Servo Controller. The lever telegraph and the

push button telegraph communicate on the same network.

Command Position

Optional command signal transmitters can be installed at

the factory. These transmitters work independently of the telegraph

circuitry in the Digital Servo Controller. Each transmitter has it's own

power supply with a self resetting internal fuse. Even with a complete

failure of other circuitry on the Digital Servo Controller the transmitter

will continue to function properly.

Diagnostics

Troubleshooting guidance is provided by a Watchdog LED and

a Fault Code LED. Under normal operating conditions the Watchdog LED will

flash.

The Fault Code LED flashes two digit codes which

correspond to particular fault conditions. A fault relay opens on a general

system fault. |